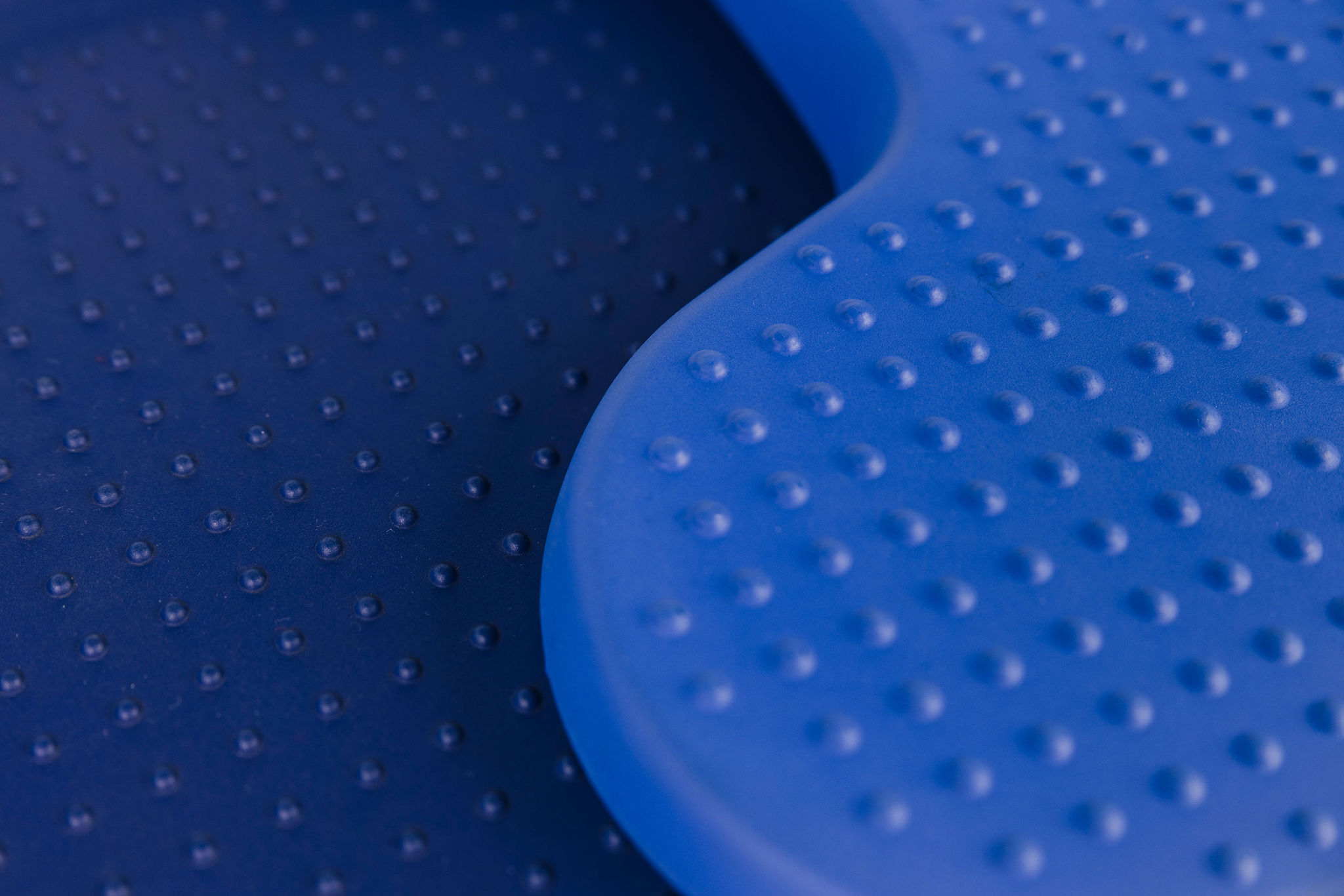

Polyurethane is durable

Polyurethanes are usually characterized by very good wear resistance, high elasticity, chemical resistance and resistance to oil, resistance to both low and high temperatures, resistance to weather, wind and UV radiation, non-static, good insulation and sound dampening ability.

Polyurethane elastomers have properties that in many cases match and surpass rubber. Polyurethane is also very suitable for embedding sensitive electronics in exposed environments.

A polyurethane based on polyether is hydrolytically stable, this means that it is not broken down by water, which has made polyurethanes common details in underwater environments. With the help of various additives, the material can also be fire rated.

Polyurethane compared with other materials

Polyurethane VS rubber

- Polyurethane has a longer durability – especially where the detail is exposed to stretching or other stresses

- Higher number of cycles for repeated loading

- Significantly lower casting costs

Polyurethane VS metal

- Polyurethane has a lower weight, which generates lighter components and safer handling

- Polyurethane is more resistant to wear and corrosion

- More cost-effective – less maintenance and a longer lifespan

- Sound levels are minimized as polyurethane tends to absorb sound

Polyurethane VS plastic

- Polyurethane has greater abrasion resistance

- Polyurethane has elastomeric properties that plastic lacks

- Elastomeric properties also provide;

- Elastomeric memory

- Physical properties which can be engineered to meet exacting specifications